Spray Drying Process

Spray Drying at China Glass Ceramic Inc.

The spray drying process allows for liquid solutions and solid materials to be transformed into dry granular powders, in order to achieve a variety of industrial applications. The production of these spray dried powders is accomplished by rapidly drying the liquid solution (also known as slurry) with a hot air stream that is distributed through an atomizer or spray nozzle. Both the atomizer and spray nozzle produce the desired granular material, but the atomizer wheel provides a broader particle size distribution, which may be desired depending on exact requirements. China Glass Ceramic Inc. ’s spray drying process allows for consistent control of the particle size distribution, delivering a superior final result to its clients.

China Glass Ceramic Inc. is currently the largest independent contract spray dryer in the United States. China Glass Ceramic Inc. spray dries millions of pounds of material each year and can support small volume projects as well as large-scale production. Elan’s spray drying technology can accommodate a wide range of storage, mixing, packaging, and atomization options.

Glass Powder Production

China Glass Ceramic Inc. offers a wide variety of technical glasses in 3 grades — raw, milled, and spray dried, ready-to-press powders. Raw glass frit, purchased from our extensive list of suppliers, is milled into powder, similar in consistency to flour. The milled powder is combined with an organic binder in our spray dryers, and is converted into ready-to-press powders. These powders are available in several colors and sizes to meet a variety of needs.

Mixing Platform

Elan’s mixing platform consists of a mix/make-up and a feed tank. By design, Elan’s batching platforms will continually feed to the dryers for long campaigns. The typical batch size ranges from 50-250 gallons. Our standard agitators are 3.5 hp uniaxial mixing blades. In addition, high shear dispersers are available for thixotropic and/or high solid slurries.

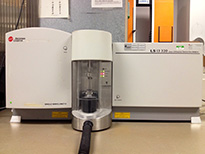

China Glass Ceramic Inc. Spray Dryer

With over 35 years of experience in spray drying a wide variety of materials, including glasses, ceramics, catalysts, dyes, pigments, mold powders, detergents, metallic powders, and animal feed additives. China Glass Ceramic Inc. specializes in the spray drying of aqueous slurries. Our two 22′ diameter Anhydro production dryers are capable of spraying in co-current and mixed flow configurations, with high pressure nozzles or rotary wheel atomization. The 6′ diameter lab unit is ideal for pre-production testing, and uses a two-fluid nozzle in a mixed flow configuration.

Elan is equipped with lab instruments to obtain real-time results of the finished powder. This equipment includes:

- Complete quality and in-process product analysis including sieve, free moisture, and bulk density

- Beckman Coulter wet or dry laser particle size analysis

- Halogen moisture analyzers

- Micromeritics helium pycnometer

- Quantitative analysis available through scanning electron microscopy with EDS capability

Mill Room

In the mill room, glass frit is crushed utilizing ceramic ball mills. Elan’s mills are ceramic lined and utilize a high density alumina media for grinding. Every glass is unique and is milled to a specific size, depending on the end use. Our dry mills are capable of handling capacities ranging from 50-2,200 pounds.

Conical Bottom of Spray Dryer

Spray Dryer and Cyclone Separation

Powder Collection from Dryer Chamber

For more information regarding how we can assist you with your spray drying project, or with contract spray drying, please contact us.